Getting Started, Load Development

Load Development

Load development as it states, is hand loading a specific set of components to suit your. In doing so you achieve a level of accuracy that factory ammunition can't measure up to. You will also be able to tailor your hand loads to your specific shooting needs & requirements.1. Before we start we need to touch on some fundamental points. That your rile and barrel are in

good condition well cleaned & cared for also that the same rile is well bedded, be it a factory job or amateur or professionally bedded aftermarket.

2. One key point to keep in mind. Some of the most accu-

rate ammunition in the world is that as used for Bench Rest matches and it is loaded with hand dies and a small mallet or arbor press often loaded at the range. You are responsible for the quality of ammunition you load. Good quality control in your reloading technique and constancy batch to batch will keep you right on target.

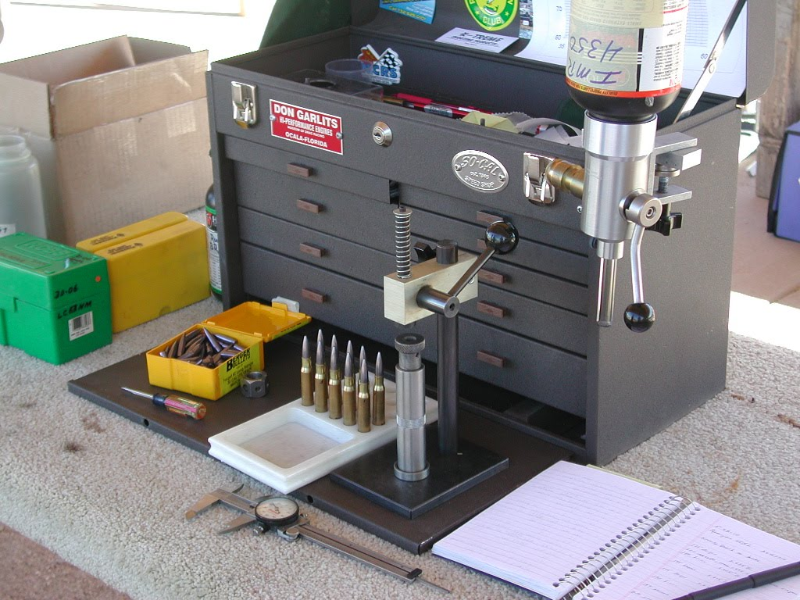

3. KEEP A NOTEBOOK !!!!!!!!!! We will imagine everybody

has their press & dies all set up, our test case will be the ever popular 308 Winchester cartridge. And the rifle

will be a Ruger American wearing a 3-9 Leupold scope. We tailor our loads for Fallow Deer.

4. As Fallow are very light bodied we will opt for a 125 grain Nosler Balistic Tip projectile. In an attempt to

get full expansion and therefore full energy transfer.

5. We will be using Remington brand brass. (When you select brass, make sure it is all of the

same type/head stamp as brass varies in internal dimension from manufacture to manufacturer, and that will make your results very inconsistent and hard to develop any lasting results with. This consistency needs to be applied to the type of powder and primer you choose also.

6. We will use Winchester large rile primers & ADI 2208 powder Step By Step

1 Starting with 20 once fired brass, we will neck size them as neck sizing makes the brass last

longer and certainly aids accuracy These cases must be previously fired in your rifle , do not use cases fired in another rifle without first full length sizing.

2 Clean primer pockets

- Seating primers is best completed using a hand tool, as press seating systems lack any sensitivity through compound linkages and one can very easily crush the priming compound against

- Weighing Powder the good book states 50 grains is a MAX load for ADI 2208 powder behind a 125 grain projectile at a NOM 3135 fps. We will stay on the right side of a maximum listed load and try

- Seating projectiles some earlier groundwork will be required before starting to seat projectiles in your (test batch) loads. Projectile seating depth is a complex question to answer, let alone short Blog article. In short the closer the projectile is to the rifling lead the more accurate but presure signs will show sooner. The further away from the rifling the projectile is seated there is less likely to be a drop in potential accuracy but preasure signs should be less likely to be an issue when nearing maximum powder load.

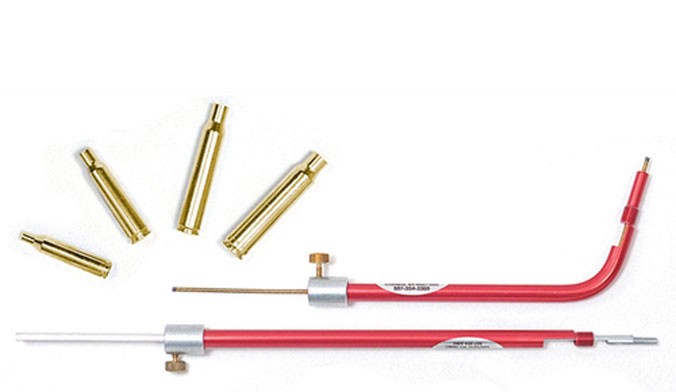

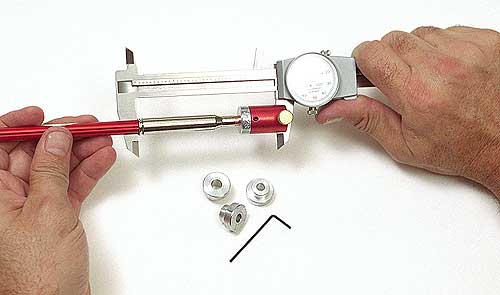

Hunting cartridges tend to perform with a small jump to the riling giving the best combination of speed & accuracy. Determining the correct seating depth is tricky by far the simplest way I have found is to buy a Hornady OAL Gauge and bullet comparitor.

Along with a good Dial of Electronic Caliper. Projectiles can be accurately seated in out or against the lands of the riling. The text below is a description of how the Hornady O.A.L. works is taken directly for Hornady’s web site as I feel they do a better job of explaining its operation than I could, link below.

Here's how the 0.A.L. Gauge works:

- Thread the Modified Case onto the O.A.L. Gauge and slip a bullet deep into the case neck.

- Remove the bolt from your rile, then slip the Modified Case/ Gauge assembly all the way forward into the chamber. At this point the bullet has not been moved toward the riling.

- Now, gently slide the internal plunger rod on the O.A.L. Gauge until it pushes the bullet into contact with

The result is the longest combination of case and bullet that can be fit into the chamber without a preload on the bullet. The results are easily measured with your caliper.

If you load bullets .020" shorter than the result, the bullets will "jump" .020" to the riling ECT. This tool is simple use and gets the job done.

There are a couple of other methods to work up cartridges over all loaded length. One is to size a cartridge & heavily chamfer the in side of the neck drop your projectile of choose into the chamber of your rile and carefully close the bolt on a sized BUT UNPRIMED! case behind the projectile. (Without opening bolt) turn rile muzzle up & carefully place cleaning rod down the muzzle until

it touches projectile tip. While placing a small amount of pre load on cleaning rod lift bolt handle what should drop out should be a dummy cartridge with projectile seated on the lands of your rile. By measuring and then seating the projectile in an extra 20 to 30 thou you have created your own dummy cartridge with a small amount of jump to the lands.

That you will be able to keep and use in the future to reproduce your hand load only with this specific set of components. Keeping in mind this dummy round will only work if you use reputable manufactures dies like Lee , Hornady , RCBS & Lyman. The seating stems of these manufacturers seat the projectiles by pushing them only on the ogive of the projectile not the tips witch can vary

in length. It is best to keep that dummy to reproduce your hand load because if you were to take measurement this can vary a lot as projectile tips can measure very differently from batch to batch or even projectile to projectile.

As means of working out O.A.L. this method is no where near as good as Hornady O.A.L. gauge. If you can afford the Hornady O.A.L. gauge buy it, all up it will save a lot of heart break and when you state that your projectiles are 3 Thou off riling lands they will be exactly three Thou off. So once you have worked your riles over all loaded length out you can seat your projectiles.

Take some time placing case into the shell holder and placing carefully lining up your projectile in case mouth before pushing press handle down to seat your projectile consistency helps do not push handle down quickly on a couple of cases and then slowly on the next four. Slowly and all the way to the press you are using travel stop works best. When you have done this for your 20 test cases you will require a cool clear morning with little or no wind also set of sandbags a tarpaulin & target 100 Yards away.

6 Load testing a bench rest would be better but this article is being written for hunt- ers. Not target shooters and most hunters do not have access to a bench rest if time is taken in setting your self up you will be able to gain meaningful results to base you findings on. As mentioned above spend plenty of time setting your self

up more time spent in preparation will save having to repeat this experiment if you get inconclusive results. (Due to not being comfortable and not shooting well or the many other problems that can cause inconsistent results).

If each group of 5 different powder weights are carefully shot the result on paper should hopefully show the cases loaded with Group @46 grains 1.8 primer show-

ing no signs of pressure Group @47 grains 1.2" primer starting to latten Group @48 grains 0.9" further lattening Group @ 49 grains only two shot 1.9" lattened & cratered primer and excessive case head expansion

If you load bullets .020" shorter than the result, the bullets will "jump" .020" to the riling ECT. This tool is simple use and gets the job done.

There are a couple of other methods to work up cartridges over all loaded length. One is to size a cartridge & heavily chamfer the in side of the neck drop your projectile of choose into the chamber of your rile and carefully close the bolt on a sized BUT UNPRIMED! case behind the projectile. (Without opening bolt) turn rile muzzle up & carefully place cleaning rod down the muzzle until

it touches projectile tip. While placing a small amount of pre load on cleaning rod lift bolt handle what should drop out should be a dummy cartridge with projectile seated on the lands of your rile. By measuring and then seating the projectile in an extra 20 to 30 thou you have created your own dummy cartridge with a small amount of jump to the lands.

That you will be able to keep and use in the future to reproduce your hand load only with this specific set of components. Keeping in mind this dummy round will only work if you use reputable manufactures dies like Lee , Hornady , RCBS & Lyman. The seating stems of these manufacturers seat the projectiles by pushing them only on the ogive of the projectile not the tips witch can vary

in length. It is best to keep that dummy to reproduce your hand load because if you were to take measurement this can vary a lot as projectile tips can measure very differently from batch to batch or even projectile to projectile.

As means of working out O.A.L. this method is no where near as good as Hornady O.A.L. gauge. If you can afford the Hornady O.A.L. gauge buy it, all up it will save a lot of heart break and when you state that your projectiles are 3 Thou off riling lands they will be exactly three Thou off. So once you have worked your riles over all loaded length out you can seat your projectiles.

Take some time placing case into the shell holder and placing carefully lining up your projectile in case mouth before pushing press handle down to seat your projectile consistency helps do not push handle down quickly on a couple of cases and then slowly on the next four. Slowly and all the way to the press you are using travel stop works best. When you have done this for your 20 test cases you will require a cool clear morning with little or no wind also set of sandbags a tarpaulin & target 100 Yards away.

6 Load testing a bench rest would be better but this article is being written for hunt- ers. Not target shooters and most hunters do not have access to a bench rest if time is taken in setting your self up you will be able to gain meaningful results to base you findings on. As mentioned above spend plenty of time setting your self

up more time spent in preparation will save having to repeat this experiment if you get inconclusive results. (Due to not being comfortable and not shooting well or the many other problems that can cause inconsistent results).

If each group of 5 different powder weights are carefully shot the result on paper should hopefully show the cases loaded with Group @46 grains 1.8 primer show-

ing no signs of pressure Group @47 grains 1.2" primer starting to latten Group @48 grains 0.9" further lattening Group @ 49 grains only two shot 1.9" lattened & cratered primer and excessive case head expansion

STOP (You would be best to cease firing the rest loaded at 49 grains) Some riles will shoot better than others some hunters will expect more than others hunter do. But looking at the groups listed above 46 grains shows a poor level of accuracy 47 grains accuracy is getting better with a small level of pressure starting to show. 48 grains shows a good turn of speed with acceptable pressure levels and excellent accuracy. 49 grains pressure has increased dramatically to a level where the shooter should be thinking seriously about not firing the remaining three loaded shells and disposing of them safely or pulling the projectiles and dropping the powder to an acceptably safe pressure level and accuracy is starting to drop off.

We can see 48 grains is accurate and fast. I would reload 20 at 48 grains retest and if the results were as conclusive as the first outing I would re-zero rile for this combination. It is that easy to develop a load specifically for the circumstances you are hunting. This can only add to your

enjoyment and the sense of accomplishment you receive from hunting.

Scott Stonex

Warning All the reloading data in this article should be used with caution. Never use the heaviest recommended powder charge until lighter charges of the same powder have been tried and found to be safe in each individual gun. All data contained herein is derived from various sources and is believed to be entirely safe when used in properly maintained firearms that are in good mechanical condition and chambered for the respective cartridge.

Since neither the author nor publisher have any control over choice of components, the manner in which they are assembled, or the arms the resulting ammunition may be used in, no responsibility- either expressed or Implied- is assumed for the use of this data.

www.reloaders.co.nz

Comments